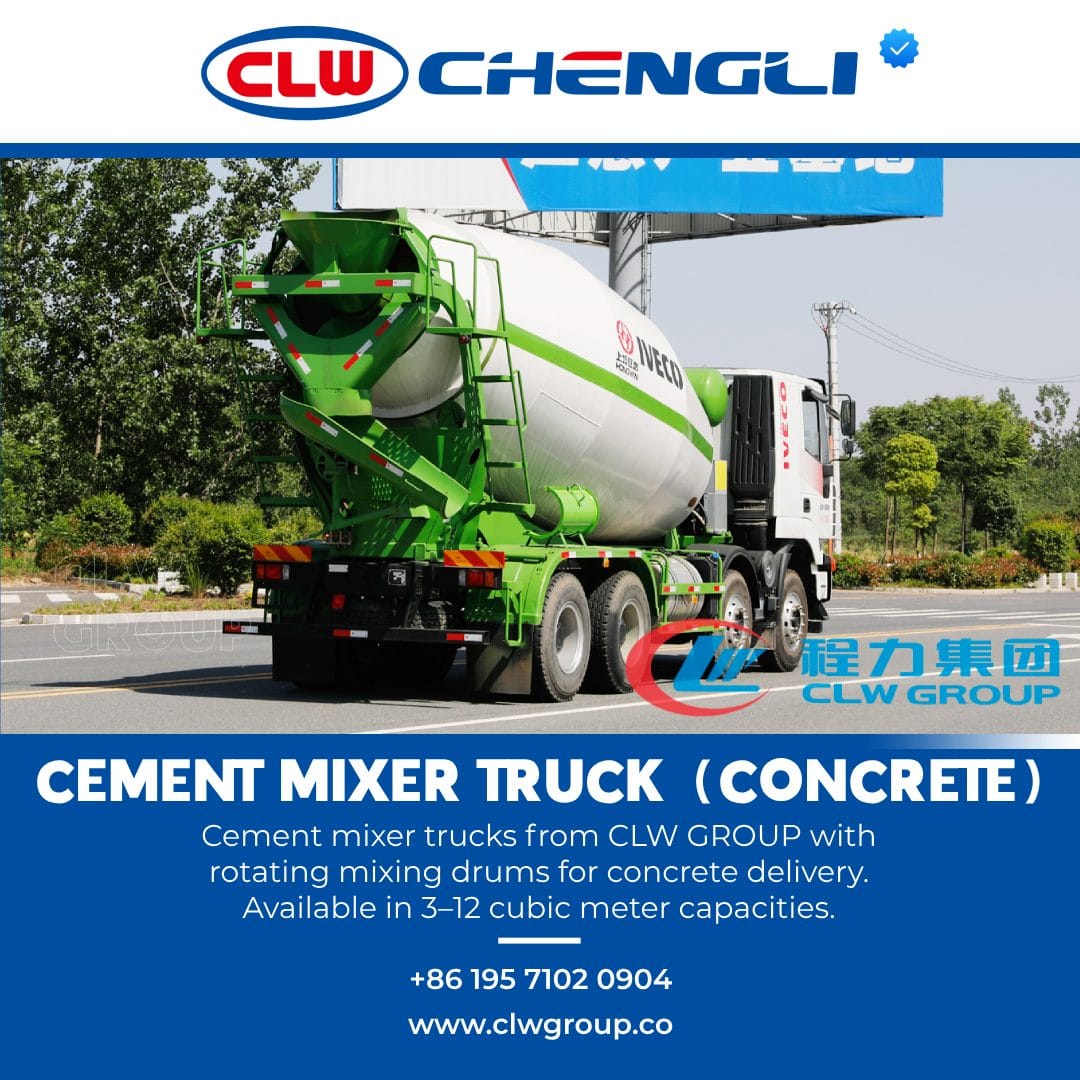

Cement Mixer Truck / Concrete Mixer – Transit Drum for Construction Sites

Cement mixer trucks from CLW GROUP with rotating mixing drums for concrete delivery. Available in 3–12 cubic meter capacities, with reliable drum drive systems and chassis from Dongfeng, Sinotruk, Isuzu, FAW, and others.

Built to Pour, Powered to Perform

CLW GROUP Cement Mixer Trucks are designed to transport ready-mix concrete safely and efficiently from batching plants to construction sites. With high-strength mixing drums, heavy-duty hydraulic drives, and consistent rotation, these trucks ensure fresh and homogeneous concrete delivery every time.

Key Features:

✔️ Mixer capacities from 3m³ to 12m³

✔️ High-tensile steel mixing drum with anti-corrosion coating

✔️ Hydraulic drive system (ZF / ARK / Eaton)

✔️ Rear platform with ladder and water tank

✔️ Mounted on durable chassis from CLW, Dongfeng, Sinotruk, FAW, and Isuzu

Engineered for stability, easy cleaning, and high performance, this mixer truck is an essential asset for any concrete supply fleet.

Technical specifications:

| Specification | Details |

|---|---|

| Chassis Brand | CLW, Isuzu, Sinotruk, Sitrak, HOWO, Shacman, Dongfeng, FAW, Foton, Beiben, JAC, JMC |

| Drive Type | 4×2, 6×4, 8×4 |

| Mixer Capacity | 3 – 12 cubic meters |

| Drum Material | Q345 steel / Wear-resistant alloy |

| Hydraulic System | ZF / ARK / Eaton |

| Water Supply | Pressurized tank / Self-flow |

| Feeding Height | ~2,600 mm |

| Discharge Speed | ≥2 m³/min |

Cement Mixer Truck / Concrete Mixer – Transit Drum for Construction Sites

Introduction to Cement Mixer Trucks

Cement mixer trucks, also known as concrete mixer trucks, play a vital role in the construction industry. These heavy-duty vehicles are designed to transport and mix concrete while en route to construction sites. The combination of a rotating mixing drum, hydraulic systems, and rugged chassis makes the cement mixer truck indispensable in delivering high-quality and consistent concrete.

Whether you’re a construction professional or a logistics coordinator managing a fleet, understanding the capabilities, types, and technical aspects of mixer trucks can significantly improve operational efficiency and reduce maintenance costs. This guide explores everything you need to know about cement mixer trucks, from design to deployment on construction sites.

Understanding the Purpose of Concrete Mixer Trucks

Mixer trucks are specially engineered to mix and transport concrete without compromising the quality of the material. The core of the system lies in the rotating mixing drum, which ensures that the concrete remains in a liquid state until it is ready for discharge at the construction site.

These trucks are equipped with powerful hydraulic motors to rotate the drum and often feature rear discharge or front discharge designs, depending on site requirements.

Key Components of a Cement Mixer Truck

The Drum

At the heart of every concrete mixer truck is the mixing drum. This drum is usually constructed from wear-resistant steel and features internal blades to keep the mixture in motion.

Hydraulic Systems

Hydraulic systems control the drum’s rotation speed and direction, allowing concrete to mix or discharge depending on operational needs.

Chassis & Cab

The chassis supports the overall weight of the truck and concrete load. Common configurations include 8×4, 6×4, and 4×2, each offering various payload capacities and stability for different terrains.

Discharge Mechanisms

These include rear discharge, front discharge, and side discharge systems. Some trucks use chutes for extended reach during concrete transport.

Types of Mixer Trucks

Rear Discharge Mixer

This is the most commonly used cement mixer truck configuration. It offers simplicity in design and is widely preferred for its durability and high capacity.

Front Discharge Mixer

Front discharge mixers are gaining popularity due to their ease of control and the ability to be remotely operated from the driver’s seat.

Portable Concrete Mixers

These small-scale portable units are ideal for construction in tight urban spaces or remote locations. They offer flexibility and are often electric or diesel powered.

Concrete Mixer Truck Configurations

8×4 Cement Mixer Truck

This high quality configuration supports heavier loads and is suitable for large-scale construction sites. It’s a common option from manufacturers like HOWO, Shacman, and Liebherr.

6×4 & 4×2 Mixer Trucks

These offer a balance between maneuverability, fuel efficiency, and payload. Ideal for mid-range transportation needs.

Cement Mixer Drums – Material & Design

Steel and Wear Resistance

The best mixing drums use wear-resistant steel with high durability. The internal design, including blades, enhances mixing efficiency.

Capacity

Common capacities range from 6 to 12 cubic meters. Larger volumes can be accommodated using trailers or specialized heavy-duty trucks.

Cement Mixer Truck Manufacturers

Leading Brands

HOWO

Shacman

Liebherr

Oshkosh

Each manufacturer offers unique benefits such as electric drive, electronically controlled systems, and superior hydraulic setups.

Truck Mixer for Sale

When sourcing a mixer truck for sale, consider the configuration, axle load, drum capacity, and overall fuel consumption. Look for a supplier who understands your site needs and can offer tailored solutions.

Construction Site Considerations

Loading & Discharging

Efficient loading and discharge are critical to maintaining the quality of the mixed concrete. Modern systems include electronic control units that allow the driver to manage the mix from the cab.

Site Terrain

Rough and uneven terrains require trucks with better suspension and road weight distribution to maintain stability and safety.

Safety in Concrete Transportation

Preventing Spillage and Curing

Properly designed hopper and chute systems help control spillage. Drum rotation is adjusted to keep concrete from curing prematurely during transit.

Regulatory Compliance

Ensure compliance with local road weight regulations and environmental guidelines when operating cement mixer trucks.

Maintenance & Durability

Daily Maintenance Checklist

Check hydraulic systems

Inspect drum blades and chassis

Monitor fuel and electric systems

Clean chutes and hopper

Long-Term Durability

Use high-tensile steel and wear-resistant components for extended durability in complex working conditions.

Innovations in Mixer Truck Technology

Electric Drive Systems

Environmentally friendly and efficient, electric drive systems are ideal for urban transportation.

Remotely Controlled Operations

Modern trucks can be operated electronically via onboard systems or remote interfaces, enhancing safety and precision on-site.

Applications in Modern Construction

Concrete mixer trucks are essential for:

Residential and commercial buildings

Infrastructure projects like bridges and roads

Remote construction sites

Emergency repairs and disaster relief

Fleet Management & Logistics

Fuel Efficiency

Opt for trucks with optimized fuel usage, efficient drive trains, and reliability over long distances.

Flexible Configurations

Choose from portable, trailer-based, or rear discharge systems depending on your project scale and timeline.

Choosing the Right Truck Mixer

Key Considerations

Axle count and configuration

Chassis strength

Drum capacity

Maintenance support

Manufacturer reputation

Request a Quote

Always request a quote based on specific operational requirements to ensure cost efficiency.

CLW Group also offers a versatile curtain truck (tautliner), designed with side curtain panels for swift loading and secure transport of general cargo.Common Challenges and How to Overcome Them

Weather Conditions

Cold or hot environments affect concrete curing. Use temperature-resistant drums and monitor mix consistency.

Long-Distance Transport

Use concrete mixers with enhanced durability and stability to maintain concrete quality over long hauls.

Final Thoughts

The cement mixer truck is more than just a vehicle — it’s a mobile concrete production and delivery unit. With the right configuration, manufacturer, and maintenance strategy, these trucks can dramatically improve construction timelines, material quality, and safety standards.

You must be logged in to post a review.

Reviews

There are no reviews yet.