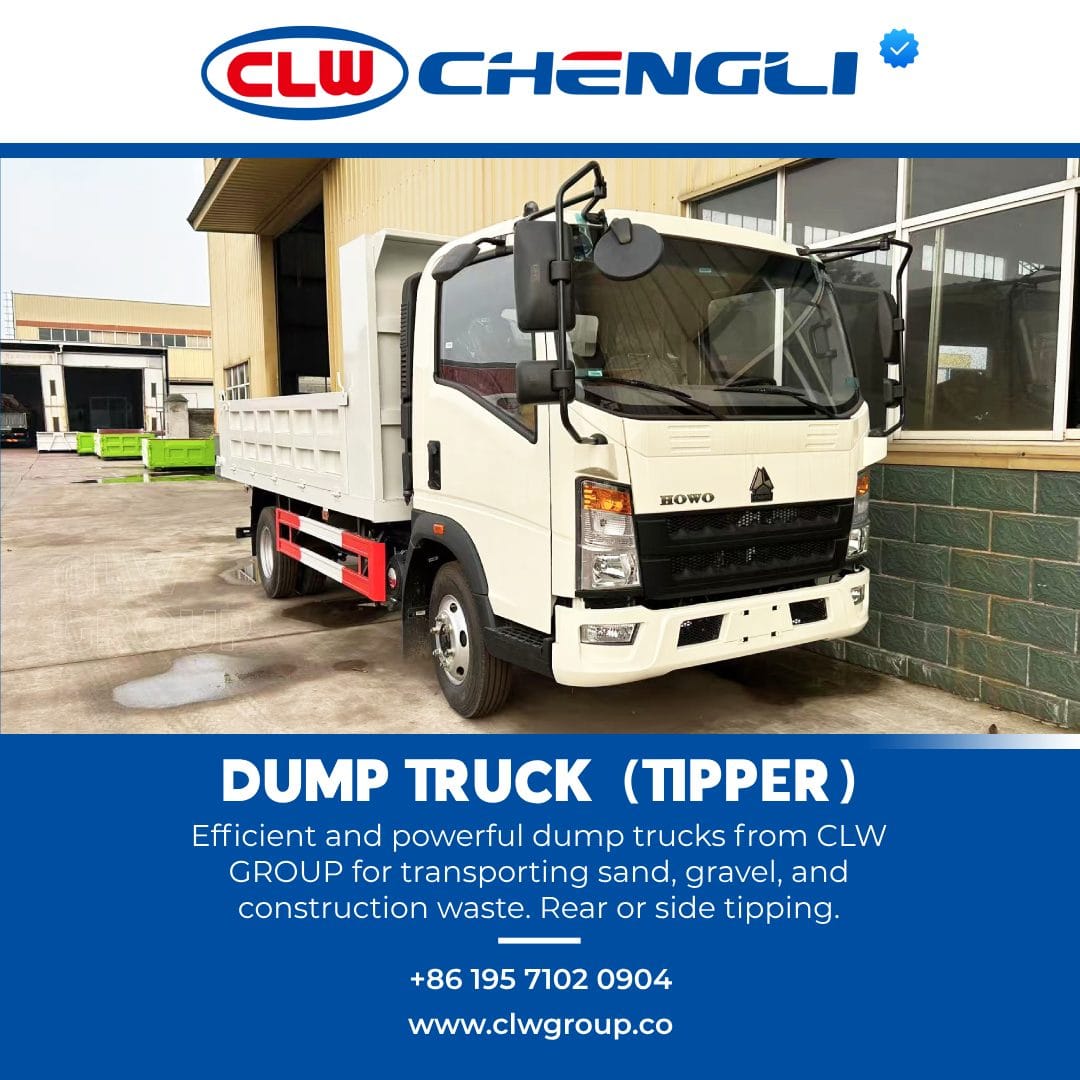

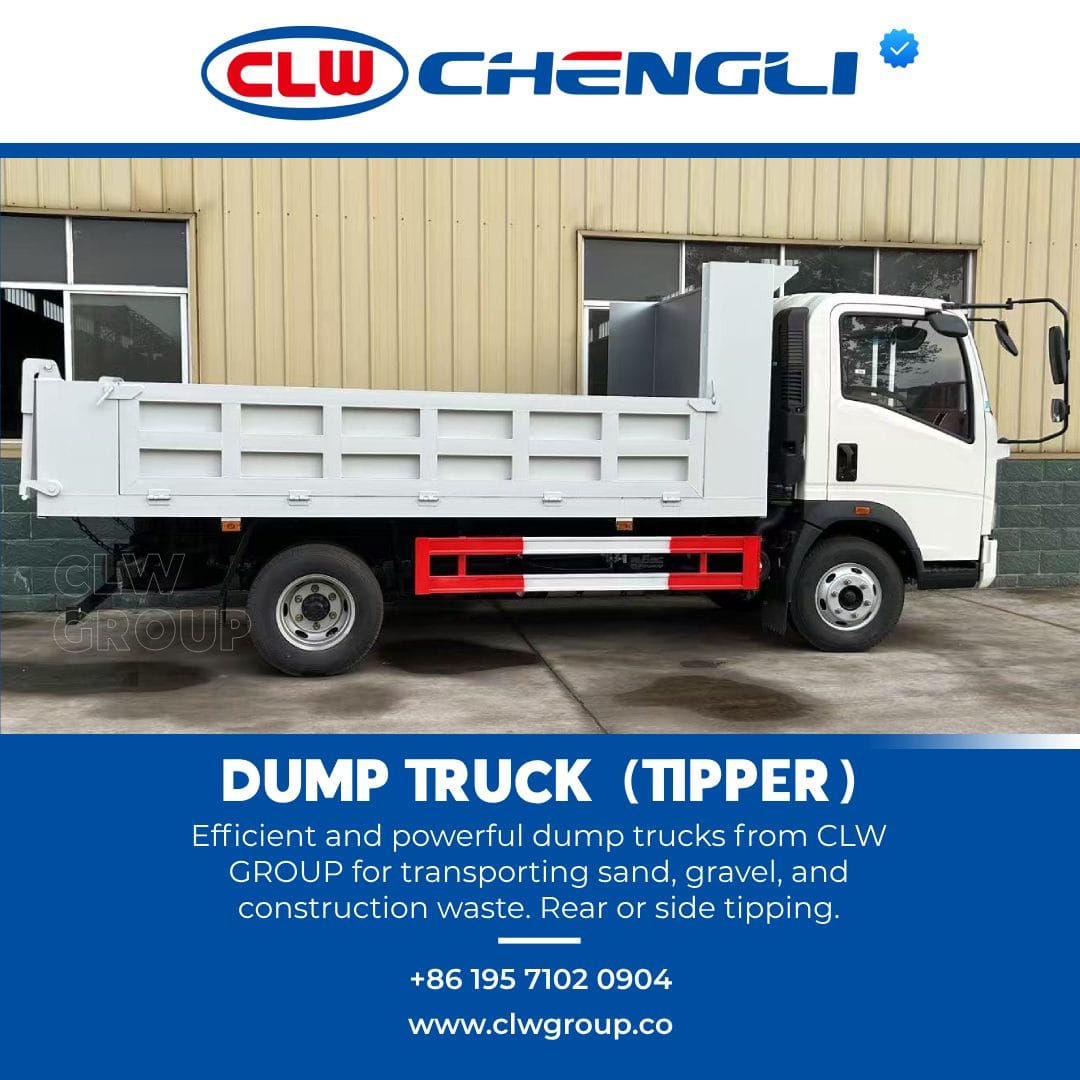

Dump Truck / Tipper Truck – Rear & Side Unloading, Heavy-Duty Options

Efficient and powerful dump trucks from CLW GROUP for transporting sand, gravel, and construction waste. Rear or side tipping, light to heavy-duty options, with chassis from CLW, Isuzu, Sinotruk, FAW, and more.

Built to Haul, Designed to Last

The CLW Group Dump Truck (also known as a Tipper Truck) is the ideal solution for transporting and unloading bulk materials such as sand, gravel, soil, or demolition debris. These trucks are designed for efficient material discharge with high lifting capacity and robust structure.

Key Features:

✔️ Available in rear tipper and side tipper variants

✔️ Light, medium, and heavy-duty models available

✔️ Hydraulic lifting system with reliable cylinders

✔️ Chassis options from CLW, FAW, Dongfeng, Sinotruk, Isuzu

✔️ Best suited for mining, construction, and infrastructure projects

Each dump truck is manufactured with reinforced bodywork, advanced hydraulics, and powerful engines for tough jobs.

Technical specifications:

| Specification | Details |

|---|---|

| Chassis Brand | CLW, Isuzu, Sinotruk, Sitrak, HOWO, Shacman, Dongfeng, FAW, Foton, Beiben, JAC, JMC |

| Drive Type | 4×2, 6×4, 8×4 |

| Body Capacity | 5 – 25 cubic meters |

| Payload Capacity | Up to 30,000 kg |

| Engine Power | 89 – 375 HP |

| Dump Type | Rear Tipper / Side Tipper |

| Hydraulic Lift | Front / Underbody Cylinder |

| Emission Standard | Euro III / V / VI |

Truck Dump Truck: Articulate & Rigid Options for Off‑Highway Hauling

This guide provides a detailed overview of dump trucks, including articulated dump trucks and rigid dump trucks (or tipper trucks), covering their configurations, hydraulic unloading systems, payload capacities, chassis types, and operational applications—especially in mining, quarrying, construction, and infrastructure industries. It addresses factors important to buyers searching for trucks for sale, heavy‑duty hauling options, and guidelines for selecting the right hauler for demanding jobsites.

1. Understanding the Dump Truck Landscape

Dump trucks (also called tipper trucks) are specialized hauling vehicles designed to load, transport, and unload bulk material such as gravel, aggregate, demolition waste, or excavation spoils. They are categorized into rear unloaders (most common) and side unloaders, and include both rigid dump trucks and articulated dump trucks.

1.1 Rear vs. Side Unloading

Rear dump trucks feature an open-box bed hinged at the rear, lifted by hydraulic rams to pour material behind the vehicle.

Side dump trucks tilt the open bed sideways, allowing unloading on one side—ideal for narrow or uneven jobsite conditions.

1.2 Rigid vs. Articulated Configuration

Rigid chassis dump trucks have a single, fixed frame suitable for highway-to-jobsite hauling.

Articulated dump trucks (also referred to as articulated haulers) consist of two units joined with a pivot joint enabling superior maneuverability on rough, off‑highway terrain.

Popular brands in the industry include Caterpillar, Volvo, Hitachi, John Deere, Mack, and Sany.

2. Dump Truck Specifications & Payload Capacity

2.1 Payload Capacities & Hauling Efficiency

Payload capacity defines the potential productivity:

Smaller tipper trucks may haul 10–25 tons.

Heavy off‑highway dump trucks—like articulated haulers—can handle 30–60 tons (or more) per load.

Strategic selection of cylinder size, number of axles, and hydraulic power directly impacts number of trips needed.

2.2 Powertrain & Constructions Specs

Heavy‑duty dump trucks must combine high torque powertrains with robust hydraulic systems to handle full loads and tough terrain. Typical configurations include:

Tandem or triple axle setups for weight distribution

Lift axles to adjust GVWR as loads vary

Hydraulic dump systems sized for controlled dumping and safety

Rigid frame rails to support repeated hoisting of large volumetric material

3. Key Dump Truck Components

3.1 Hydraulic System & Bed Design

Hydraulic cylinders (hydraulic rams) should be robust and sized for the heaviest loads.

Controlled dump systems let the operator regulate unloading rate.

Heavy‑duty dump bodies—often made of high-tensile steel or wear‑resistant alloy—are built for abrasive material like gravel or demolition debris.

3.2 Chassis & Suspension

Articulated dump trucks have front and rear units with flexible axles suited for rough terrain.

Rigid dump trucks ride on large chassis from brands like Caterpillar or Volvo with sturdy suspension to carry big loads on semi-smooth roads.

3.3 Tires, Steering & Cab Features

Multiple axles must be matched to high load tires, steerable front axles, and rugged suspension.

Operator cabin—often featuring lift axles and ergonomic controls—is built for safety and comfort during long haul cycles.

4. Applications in Industry

4.1 Construction & Infrastructure

Dump trucks are essential in construction projects for hauling gravel, sand, fill material, or demolition debris. Side- or rear-dumpers carry large volumes of material between jobsite zones quickly and safely.

4.2 Mining, Quarry & Aggregate Operations

In high-production environments like quarries or mines, articulated dump trucks offer greater uptime by navigating rough terrain and tight spaces. Their flexibility allows moving material even in steep or unstable areas.

4.3 Demolition & Waste Haulage

Contractors hauling demolition waste or concrete rely on sturdy dumper bodies and rear-overload protection to ensure safe dumping, even on uneven ground. Frequent tipping cycles are supported by high-capacity hydraulics.

5. Choosing the Right Dump Truck

5.1 Matching the Right Format

Decide between rigid, articulated, or side dump based on:

Site terrain (flat vs. rough)

Type and volume of material

Access width and turning radius

Required load cycles per hour

5.2 Brand and Model Variants Available

Major trucks makes and models include:

Caterpillar 725 (articulate)

Volvo A40G (articulate)

John Deere 460E (rigid)

Mack Granite Dump Truck

Sany 30‑60 ton articulated haulers

Dealers and trucks for sale listings offer both new and heavy-duty options across these models.

5.3 Hydraulic & Safety Features

Look for critical design elements including:

Load-limiting valves

Emergency tilt lock mechanisms

Rear visibility aids

Cab rollover protection and operator ergonomics

6. Operational Productivity & Cost Efficiency

6.1 Cycle Time & Hauling Cost

Heavy-duty dump trucks improve productivity by increasing payload, optimizing cycle time, and reducing trips. Efficiency increases when trucks are sized correctly for the haul distance and the material being moved.

6.2 Uptime & Maintenance Considerations

Long-lasting uptime relies on:

Routine maintenance of hydraulic pumps and hoses

Inspecting suspension, tires, and frame rails

Access to spare parts from reputable manufacturers and dealers

Training operators in best practices for controlled dumping and load balancing

7. Specialized Configurations & Options

7.1 Side and Quad-Axle Dump Trailers

When flexibility is needed, dump trailers with side-unload and quad axle setups offer large volumes and stable transport for long-volume haulage.

7.2 Mini and Specialized Dumpers

Smaller job sites may use compact articulated dump trucks or mini‑dump trailers with capacities as low as 5–8 tons, perfect for tight construction zones.

7.3 Boom & Crane Integration

Some truck-mounted crane variants are equipped with dumping capability, enabling lift and dump combos that can handle cargo and unloading from vehicle-mounted crane lifts.

8. Environmental and Safety Regulations

8.1 Emission & Noise Regulations

Modern designs include Tier‑4 compliant engines and low-noise formats, especially critical in urban work zones or residential areas.

8.2 Safety Certifications

Compliance with ISO and OSHA standards ensures load safety, cab integrity, and operator protection during routine and emergency operations.

9. Total Cost of Ownership & Purchase Tips

9.1 Comparing New and Used Dump Trucks

New trucks for sale provide warranties, modern hydraulics, and latest emissions tech.

Used dump truck options can reduce upfront cost—but critical mechanical inspection is essential for value retention.

9.2 Fuel Efficiency & Engine Performance

Look for powertrains optimized for torque and fuel economy: engines rated with appropriate horsepower and torque to manage full payloads over repeated cycles.

10. Case Stages & Best Practice Models

10.1 Quarry Project Simulation

For example, a quarry using a fleet of articulated haulers—capacity 40 tons—can reduce load cycles by half, improving operational speed and reducing wear on equipment.

10.2 Construction Site Logistics

Rigid dump trucks with side‑unloading and multi-axle chassis can move fill materials along narrow corridors more effectively than standard rear-dump due to controlled discharge.

11. Maintenance, Dealer Support & Spare Parts

11.1 Access to OEM Support

Companies like Caterpillar, Volvo, or Sany offer global dealer networks for spare parts, training, and service support—crucial for uptime.

11.2 On-Site Operator Training Programs

Proper training helps reduce hydraulic wear, minimize tipping accidents, and optimize use of dump body controls and braking systems.

12. Future Trends in Dump Truck Design

12.1 Hybrid & Electric Tipping Systems

Next-gen dump trucks may introduce electric or hybrid powertrains integrated with hydraulic dump systems for reduced emissions and lower running cost.

12.2 Smart Telematics and Payload Tracking

Real-time payload weighing, cycle monitoring, onboard diagnostics, and scheduling apps improve efficiency and uptime.

Conclusion

Dump trucks—whether rear‑dump, side‑unload, rigid, or articulated—are vital workhorses in site logistics, hauling materials in sectors like construction, quarrying, infrastructure, and demolition. By understanding the differences between articulated dump trucks and rigid tipper trucks, selecting the appropriate chassis, payload capacity, and hydraulic unloading system, operators can optimize productivity, safety, and cost-effectiveness across any job site. Robust design, powerful hydraulics, and compliance with safety standards are essential hallmarks of a well‑specified dump truck solution.

You must be logged in to post a review.

Reviews

There are no reviews yet.