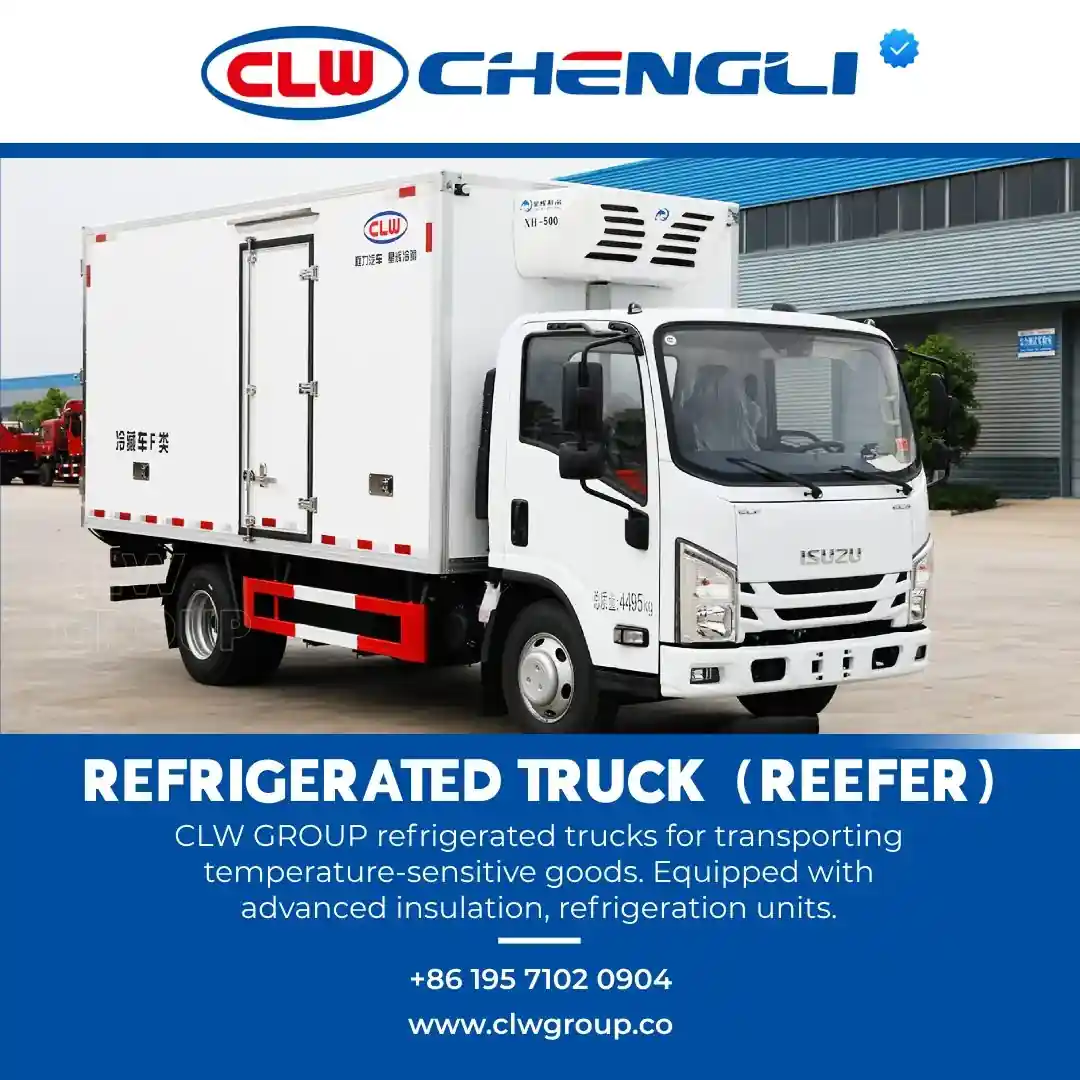

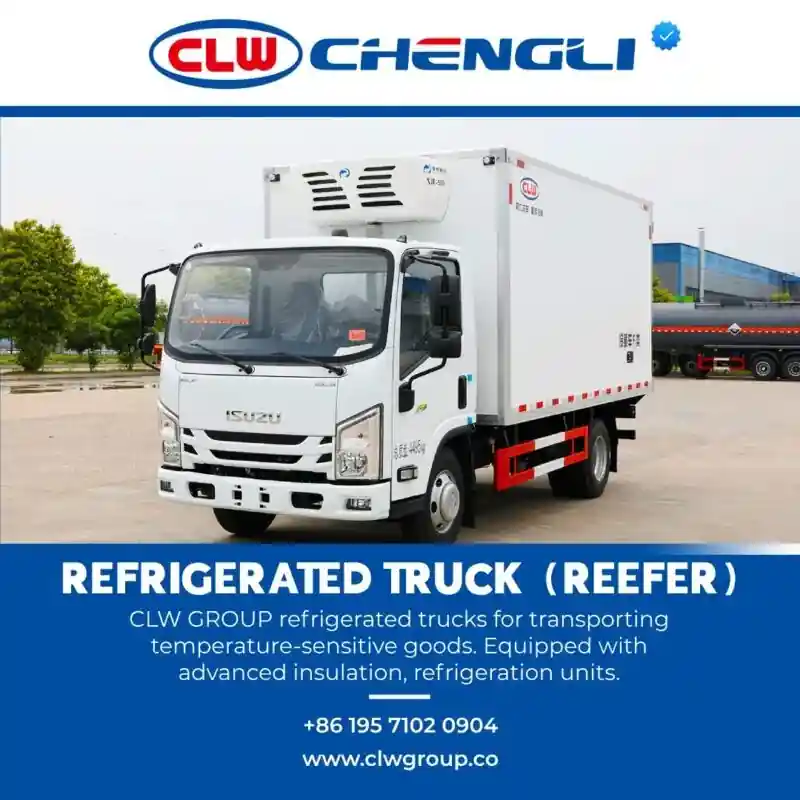

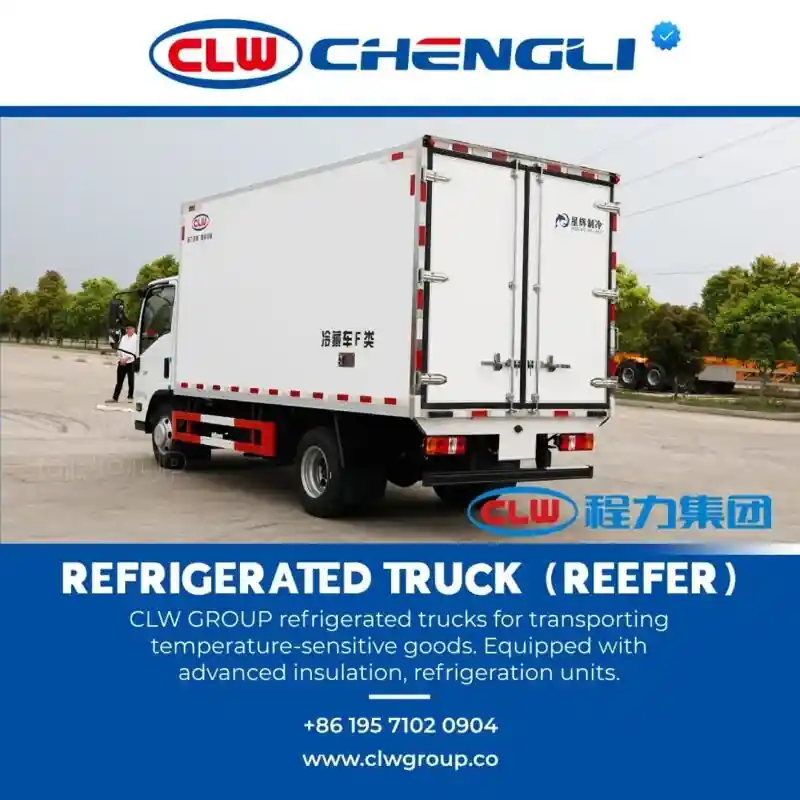

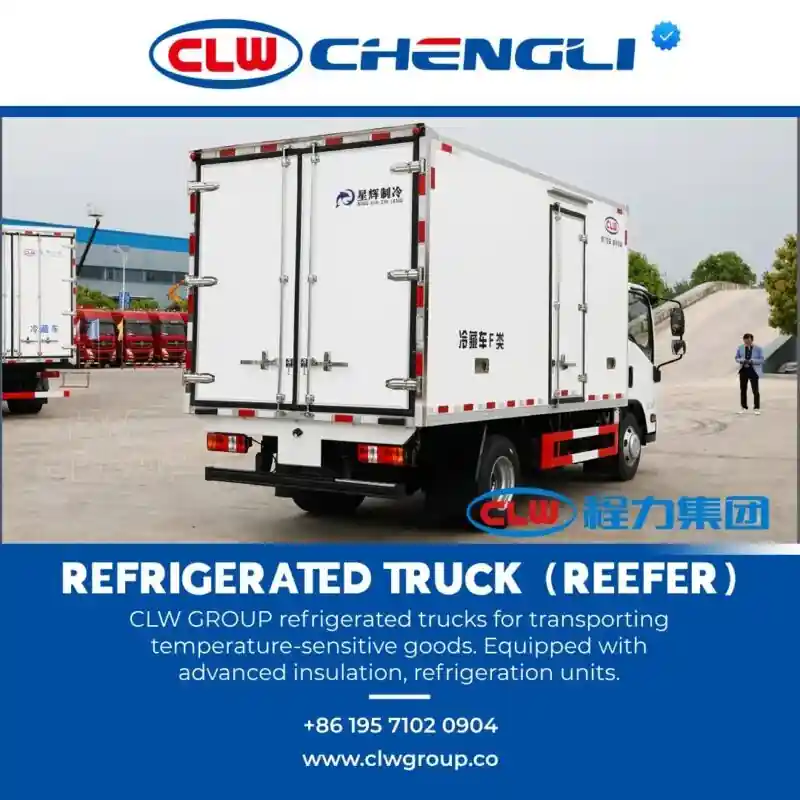

Refrigerated Truck / Reefer Truck – Cold Chain Transport for Perishables

CLW GROUP refrigerated trucks for transporting temperature-sensitive goods. Equipped with advanced insulation, refrigeration units, and multi-temperature zones. Chassis options: Dongfeng, Isuzu, Sinotruk, FAW, and more.

Keep It Cold, Deliver It Fresh

CLW GROUP Refrigerated Trucks — also known as reefer trucks — are designed for transporting perishable and frozen products at stable temperatures. From pharmaceuticals to dairy, seafood, meat, and produce, these cold chain vehicles ensure safe delivery under any climate.

Key Features:

✔️ Temperature range from -20°C to +15°C

✔️ Single or dual compartments with partitions

✔️ Insulated box with GRP, PU foam, or stainless steel lining

✔️ Carrier / Thermo King / Chinese refrigeration units

✔️ Optional GPS temperature monitoring and rear liftgate

✔️ Mounted on chassis from CLW, Isuzu, Dongfeng, Sinotruk, FAW

Reliable. Hygienic. Compliant with cold-chain transport regulations worldwide.

Technical specifications:

| Specification | Details |

|---|---|

| Chassis Brand | CLW, Isuzu, Sinotruk, Sitrak, HOWO, Shacman, Dongfeng, FAW, Foton, Beiben, JAC, JMC |

| Drive Type | 4×2, 6×4, 8×4 |

| Box Volume | 5 – 35 cubic meters |

| Temperature Range | -20°C to +15°C |

| Refrigeration Unit | Carrier / Thermo King / Domestic Brands |

| Body Material | PU Foam + FRP / Stainless Steel (Optional) |

| Compartments | Single / Dual Zone (optional) |

| Optional Features | Liftgate, Data Logger, Side Door |

Refrigerated Truck: Cold Chain Transport for Temperature-Sensitive Goods

In the global logistics industry, the refrigerated truck, also known as a reefer truck or refrigeration truck, plays an essential role in the cold chain, enabling safe transportation of temperature-sensitive goods such as pharmaceuticals, meat, seafood, dairy products, ice cream, and even flowers. Whether you’re looking for a new or used refrigerated truck for sale, or simply want to understand the engineering behind this cold transport marvel, this guide offers everything you need to know.

Understanding the Functionality of a Refrigerated Truck

A refrigerated truck is a specially designed vehicle that maintains a controlled, chilled environment inside its cargo area using reefer units powered by diesel, electricity, or gasoline. The truck body is insulated to prevent temperature loss, and advanced refrigeration systems ensure stable temperature control during long-distance travel.

Reefer Truck Technology and Refrigeration Units

The cooling mechanism in these trucks involves a refrigeration unit, typically powered by a diesel engine or electric motor. Brands like Thermo King dominate the reefer technology market with their highly efficient temperature control systems that allow for freezing or chilling cargo between -25°C to +25°C.

Insulated walls made from stainless steel or galvanized steel

Freeze protection for ice cream and meat

Vent doors to release humidity

Temperature sensors with real-time monitoring

Types of Refrigerated Trucks

Refrigerated vehicles come in multiple configurations based on size, capacity, and application. These include mini refrigerated trucks, van cargo trucks, and full-size box trucks.

Box Trucks and Cargo Vans

Box trucks are ideal for urban deliveries and short-haul transportation. These include:

Mini refrigerated trucks for retail food chains

Isuzu refrigerated truck models known for fuel efficiency

Van cargo trucks for smaller loads like pharmaceuticals and bakery items

Applications of Refrigerated Transport

Refrigerated transport serves numerous industries:

Pharmaceutical supply chains

Meat and seafood transportation

Ice cream industry and dairy

Perishable flowers and cosmetics

The cold chain must be maintained from manufacturing to delivery, making these vehicles indispensable in temperature-sensitive shipping operations.

Cold Chain Compliance and Temperature Zones

Maintaining consistent temperature is critical. Based on cargo, refrigeration trucks can be calibrated for:

Deep freeze (-25°C to -18°C) – for seafood, frozen meat, ice cream

Chill zone (0°C to 5°C) – for dairy, fruits, and vegetables

Ambient control (10°C to 25°C) – for pharmaceuticals

How to Choose a Refrigerated Truck for Your Needs

When exploring trucks for sale, consider:

Payload capacity – light-duty vs. heavy-duty

Temperature range – based on your cargo

Size of the box – small (mini), medium, or large

Fuel type – diesel or electric

Maintenance history – especially for used refrigerated trucks for sale

Used Refrigerated Trucks for Sale: What to Look For

Many businesses opt for used refrigerated trucks due to cost savings. However, certain checks are essential:

Refrigeration unit efficiency

Truck body insulation

Age and mileage

Door seals and cargo box condition

Maintenance records

Sites offering used refrigerated truck listings typically include full vehicle history and sale options with warranties.

The Manufacturing Process of Refrigerated Trucks

Manufacturers start with a chassis—commonly from brands like Isuzu, FAW, or Dongfeng. Then the insulated cargo box is mounted, followed by the integration of the reefer unit and optional features like:

Partition doors

Floor drains

GPS tracking

Automatic temperature adjustment systems

Popular Configurations: Isuzu and More

One of the most popular configurations is the Isuzu refrigerated truck, known for its:

Fuel efficiency

Compact size

Reliable chassis

Perfect for urban refrigerated transport

These trucks are used widely in Asia, Africa, the Middle East, and CIS countries for perishable delivery and retail distribution.

Market Trends and Global Use

With over 4 million refrigerated vehicles on the road globally, the cold chain sector is booming. A rising demand for frozen food, pharmaceuticals, and vaccines has driven significant investment into reefer trucks.

Global Demand Excludes Certain Markets

Note that certain Chinese refrigerated truck manufacturers do not export to:

USA

Canada

Europe

Australia

New Zealand

Japan

South Korea

Their primary markets include:

Africa

Asia

Middle East

CIS nations

Components of a Refrigerated Truck Body

Each refrigerated truck consists of:

Stainless steel or steel cargo box

Internal insulation panels

Cooling unit

Ventilation system

Temperature monitoring system

Double rear doors and side doors

Drainage pipes for melted ice

Essential Maintenance for Refrigerated Vehicles

To maintain efficiency and reliability, regular checks are needed:

Clean evaporators and condensers

Check insulation for cracks

Service diesel or electric cooling units

Monitor temperature sensors

Replace worn-out door gaskets

Comparison: New vs. Used Refrigerated Truck

| Feature | New Truck | Used Refrigerated Truck |

|---|---|---|

| Price | Higher upfront cost | Lower initial investment |

| Warranty | Manufacturer’s warranty | Depends on age and seller |

| Efficiency | Maximum cooling performance | Varies depending on condition |

| Customization | Fully customizable | Limited to existing configurations |

| Lifespan | 10+ years | Depends on maintenance history |

Refrigerated Transport and Fuel Efficiency

Given the high energy demands of refrigeration systems, fuel efficiency is a major consideration:

Diesel-powered units for long haul

Electric reefer units for urban use

Hybrid cooling systems for sustainable transport

Famous Contributor: Frederick McKinley Jones

The invention of the modern refrigeration truck system can be credited to Frederick McKinley Jones, who revolutionized cold-chain logistics by inventing a portable refrigeration unit for trucks in the 1930s. His legacy continues in every reefer unit built today.

Cold Chain Transport Challenges

Despite technological advances, the cold chain faces challenges:

Maintaining temperature consistency during loading/unloading

Handling power outages

Reducing fuel consumption

Improving insulation materials

Addressing shipping delays

Tips for Buying Trucks for Sale

If you’re looking for refrigerated trucks for sale, here’s a checklist:

Compare trucks and trailers

Consider box trucks vs. reefer trucks

Ensure availability of spare parts

Request cold unit efficiency reports

Check payload capacity and cargo box size

Insulation and Steel Material Quality

Proper insulation is critical to preserve cooling performance:

Polyurethane foam – commonly used for insulation

Stainless steel – for durability and hygiene

Sealed door frames – prevent heat infiltration

CLW Group also manufactures a fully equipped fire truck (fire engine), engineered for rapid response and superior performance in firefighting and rescue operations.Final Thoughts

From mini freezer vans to large-scale reefer trailers, refrigerated transport has transformed how we move perishable goods across regions and continents. Whether you need a used refrigerated truck or a brand-new refrigerated truck for sale, making an informed decision requires understanding the mechanics, components, and usage contexts of these specialized vehicles.

As demand for temperature-sensitive delivery grows, investing in the right truck, maintaining it regularly, and operating within an optimized cold chain network can help businesses thrive.